Gagnez en compétitivité en accélérant votre cycle de développement produit

Face à une concurrence de plus en plus forte, les fabricants industriels doivent réduire les coûts et les délais de mise sur le marché de produits devenus de plus en plus complexes alliant mécanique, électronique, informatique… nécessitant une collaboration renforcée entre services (Bureau d'études, simulation, industrialisation, achats, production, SAV…) et des équipes distantes et multi-entreprises.

Le PLM tend à optimiser les échanges, notamment en phase de conception, car il permet d’uniformiser et de centraliser les informations sur le produit dans un espace neutre et sécurisé et de structurer les rapports entre les équipes projet via des processus.

Avec Visiativ PLM, solution de gestion du cycle de vie du produit, vous réduisez votre "time to market" en favorisant la standardisation de vos produits tout en proposant la personnalisation à la commande pour répondre aux exigences de vos clients. Vous améliorez votre réactivité en améliorant la collaboration entre tous les acteurs du cycle de développement produit.

50€/h

coût d'un ingénieur BE ou méthodes

60%

des entreprises d'ingénierie ont des difficultés à recruter

80%

des utilisateurs de SOLIDWORKS PDM subissent une discontinuité des données

Sources : Xerfi, Solidworks,Syntec

Frédéric Agriodos

Chef de projet Systèmes d'information

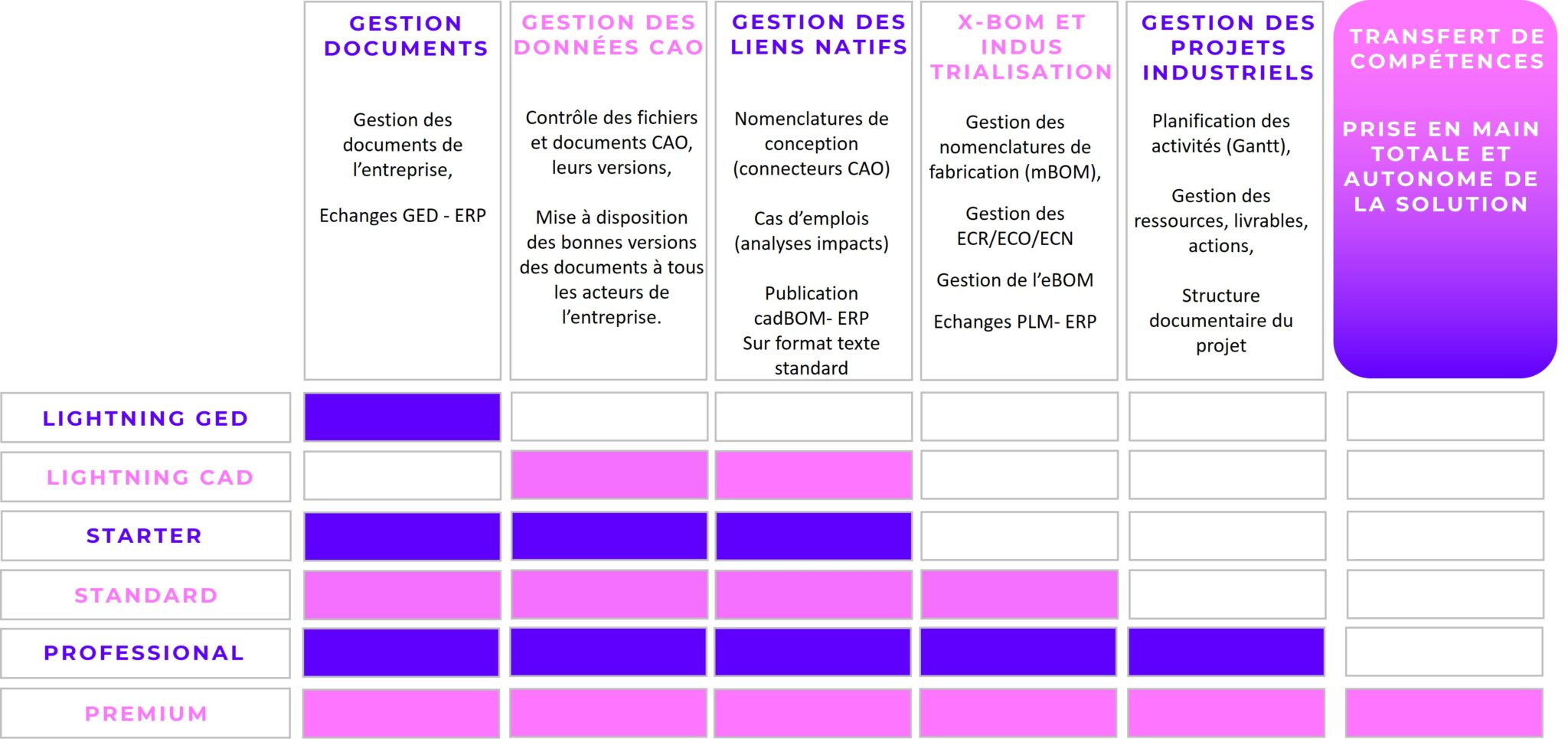

Référentiel documentaire unique des données produit, la gamme Visiativ PLM propose une solution PDM Multi CAO qui assure un accès sécurisé et rapide à l’ensemble des documents, à l’historique des versions et à la traçabilité des modifications. La solution se connecte à toutes les CAO (SOLIDWORKS, CATIA, Créo, Inventor…) ce qui permet aux concepteurs de réaliser une étude et une définition détaillée du produit.

Cette GED Technique améliore la productivité du bureau d’études par une collaboration efficace qui permet une validation fonctionnelle des produits plus rapide.

La gamme Visiativ PLM facilite l’interconnexion entre les métiers des études et de la production dont l’industrialisation, les achats et la production. Les mêmes données sont gérées dans des nomenclatures métier spécialisées : eBOM et cadBOM évoluent en mBOM et xBOM qui s’adaptent aux contraintes d’achats et de production par la synchronisation avec l’ERP.

L’industrialisation est facilitée et les dossiers de fabrication anticipés avec les fiches d’instructions et les modes opératoires accessible par tous.

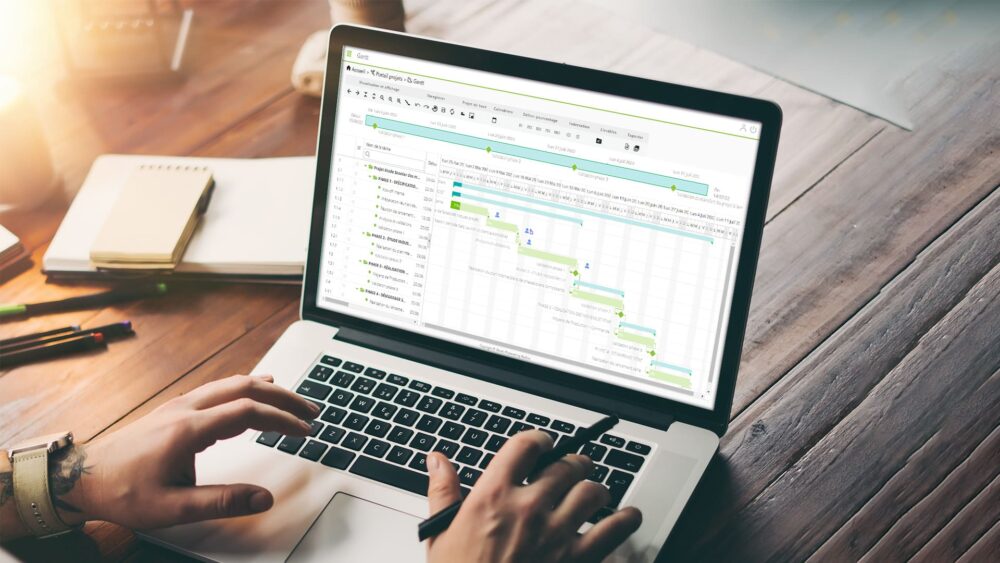

Augmentez le taux de réussite de vos projets en facilitant la collecte des informations notamment les contraintes et les exigences. La diffusion des avancées du projet est simplifiée autant avec l’externe, notamment les clients et fournisseurs, qu’avec les équipes multidisciplinaires internes pour une meilleure agilité.

La planification simplifiée améliore la gestion des jalons et des livrables autant que le suivi du budget.

Christophe JACQUES

Responsable développement CAO

Le PLM se concentre sur la gestion de l’interdépendance entre les composants du produit et l’environnement global du produit. En centralisant toutes les informations produit pour toute l’organisation, le PLM garantit que tous les acteurs impliqués ont accès aux données les plus récentes et les plus précises sans perdre de temps à rechercher l’information. Ce référentiel de données centralisé élimine les redondances, réduit les erreurs et améliore la collaboration entre les différentes équipes au sein de l’entreprise, pour une meilleure agilité lors des modifications et évolutions des conceptions.

Centralisez et partagez les conceptions CAO 3D, les articles, les BOM, les fiches de poste, pour une meilleure compréhension des contraintes de chaque discipline même dans maitriser les outils CAO.

Lorsqu’un produit évolue, on peut, en fonction de l’impact, choisir quelles nomenclatures doivent évoluer et automatiser ce fonctionnement.

L’intégration entre le PLM et l’ERP (Enterprise Resource Planning) permet un échange transparent des données entre ces deux systèmes critiques. Lorsque le PLM et l’ERP travaillent ensemble, cela offre une meilleure visibilité sur les processus métier, permettant de prendre des décisions plus éclairées. La gestion unifiée des données techniques par le PLM améliore les performances de l’ERP, optimisant la gestion des flux pour la fabrication et la logistique. Cette intégration réduit également les erreurs, améliore la productivité et permet une meilleure gestion des coûts grâce à des données centralisées et précises.

Visiativ PLM est une offre de Visiativ Innovation Engine.

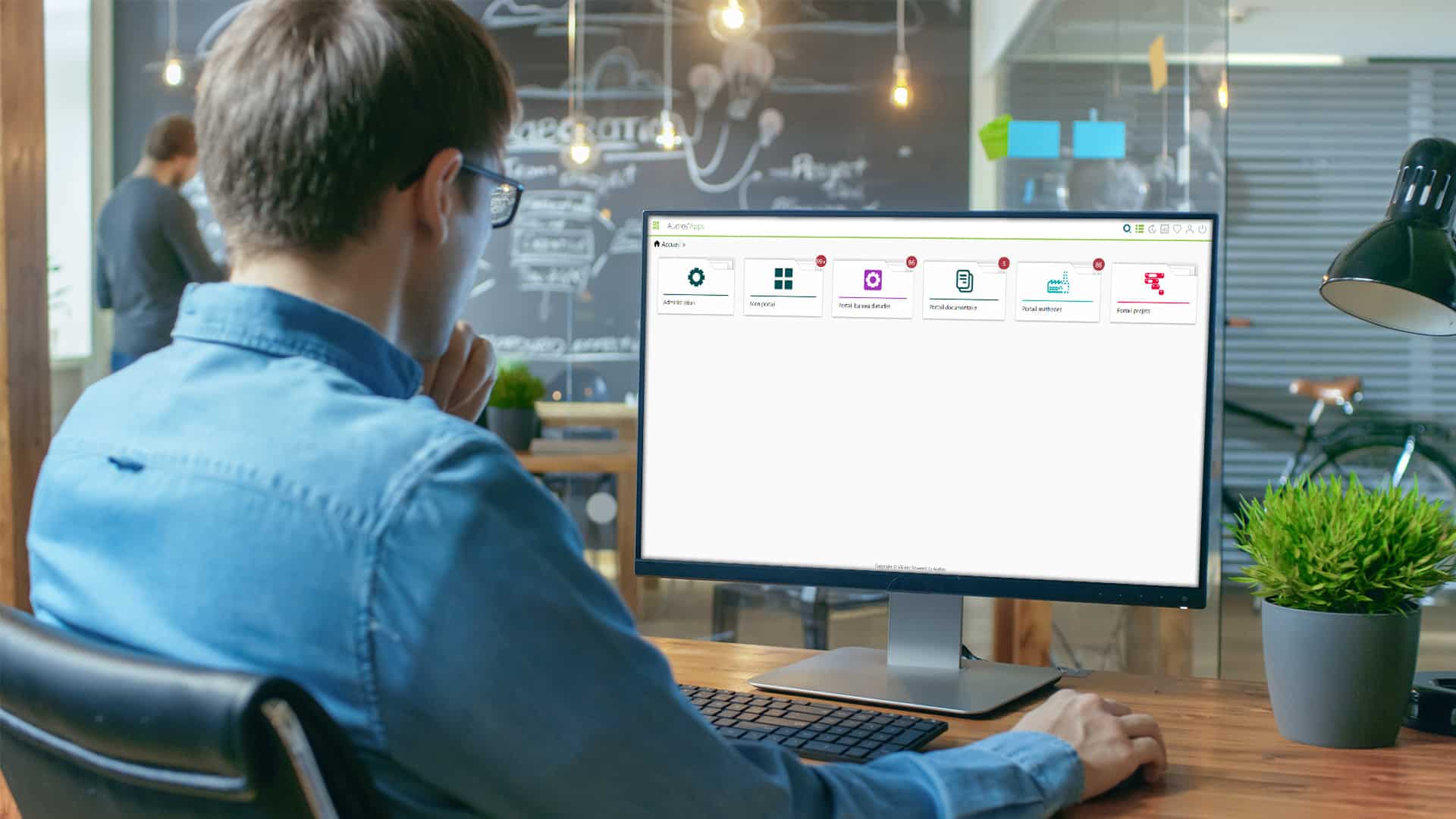

Notre plateforme d’innovation cloud offre une continuité de services pour les transformations digitales, sociales et environnementales des PME et ETI : des services et des solutions pour planifier, mettre en œuvre et piloter vos transformations, au service de votre compétitivité et de la performance de votre entreprise.

Simplifiez la gestion des informations produits et les liens entre fichiers afin d'améliorer la collaboration entre concepteurs.

DécouvrirAvec Visiativ Multi BOM gérez un référentiel unique sur l'ensemble du cycle de vie du bureau des méthodes à la maîtrise de la réalisation des produits.

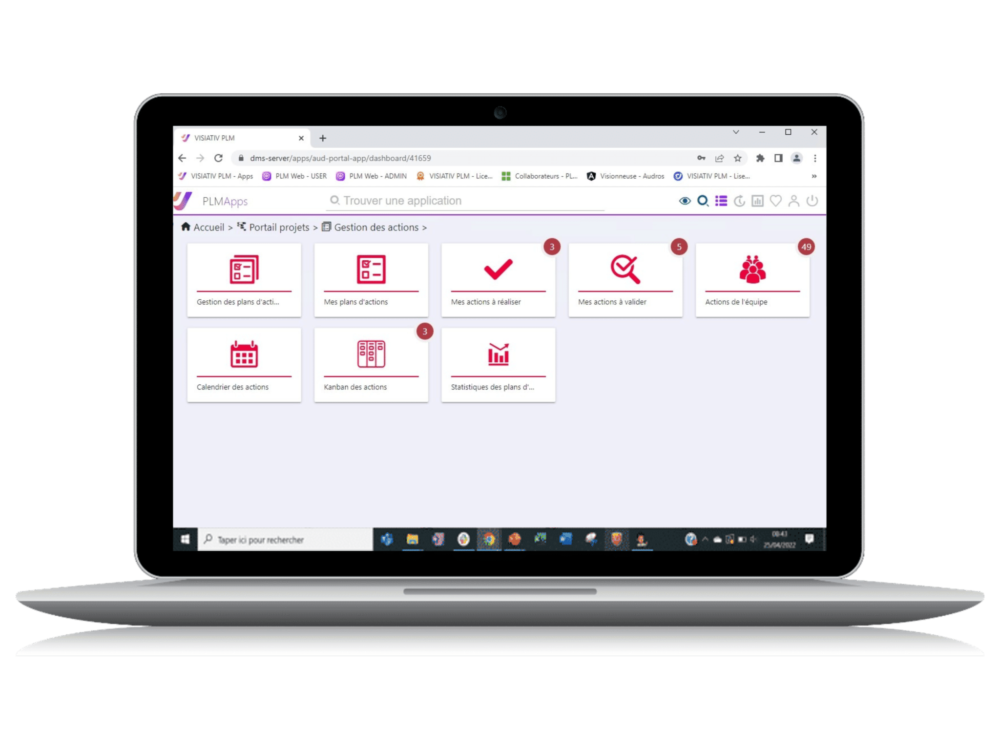

DécouvrirFacilitez la gestion de vos projets industriels en centralisant toutes les données pour préserver vos délais et vos objectifs.

DécouvrirAvec Visiativ Extension SOLIDWORKS PDM collaborez plus facilement sur les données techniques partagées avec les Bureaux d’Etudes équipés de SOLIDWORKS.

DécouvrirEn amont d'un déploiement PLM, identifier les leviers pour parvenir aux bénéfices attendus.

DécouvrirL'état des lieux des solutions et méthodologies de votre ingénierie et le plan d'amélioration.

Découvrir